Interpreting the soul of design with precise technology

High-definition black-color double-sided printing

Newly upgraded paper cutter

Overlay printing technology

|

Product |

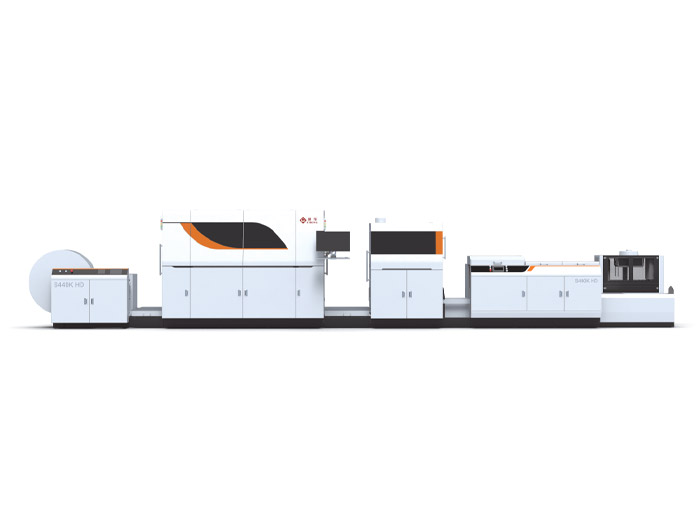

S440K HD |

Tech Parameters |

|

|

Max Image Width |

436mm |

|

Printing Type |

Black Color Double Sided(HD) |

|

Overprint Precision |

±0.2mm |

|

Printing Mode |

High Speed Mode:600dpi Production Mode:800dpi High Resolution Mode:1200dpi |

|

Printing Head |

1200dpi lndustrial HD Printing Head |

|

Ink Type |

Water Based Pigment InkJet Ink |

|

Color of Inks |

BK |

|

Highest Printing Speed * |

120m/min |

Software |

|

|

Production Software |

Including High Speed RIP (Support standard PDF file) Auto Imposition (Full-Featured Imposition is optional) softwares |

| Color Management Software | linear Color Management |

Paper Roll Supply |

|

|

Specs of Roll |

Max Roll Diameter:1270mm Width of Roll:100mm-460mm |

|

Type of Paper |

Offset Papeer、Writing Paper、Digital Paper、Newsprint Paper |

|

Weight of Paper |

50g-120g(Printing Speed Varies on Paper Weight) |

|

Other Functions |

Unwinder、Constant Tension、Unwinding Correction、Tracking on Both Sides |

Cutting Unit |

|

|

Independent Buffer Unit |

Super Long Buffer Unit(Up to 30 meters) |

|

Cutting Method |

Center Knife to Slit、Horizontal Knife to Cut Off |

|

Stacking Mode |

Fascicle Misplace Stacking |

|

Dimension of the Stack |

Width:460mm Length:140mm-660mm |

Auxiliary System |

|

|

Ink Volum Measurement |

Sectionalized Ink Volum Measurement、Real-Time Inspection |

|

Ink Supply Mode |

Intelligent Constant Pressure Ink Supply、Sectionalized Ink Supply |

|

Drying Mode |

IR Drying,Heat Oven Drying(Auto-Adjust by Speed) |

|

Liquid Cooling System |

Auto Temp Control System |

|

Quality Control System |

Inline Inspection System (Optional) |

Use of the Environment |

|

|

Host |

3 Phase 5 Wires 380V、28KW (Fully Loaded) |

|

Drying System |

3 Phase 5 Wires 380V、 68KW(Fully Loaded) |

|

Environmental Requirements |

Best Working Temp:25℃±3℃ Best Working Humidity: 40%~70%RH Non-Condensing |

|

Size** |

L11250mm x W2450mm x H2250mm |

|

Weight |

12T (Floor Load 1T/M²) |

Remark |

|

|

* |

The printing speed changes with the cutting width or paper weight |

|

** |

Distributed layout is adopted during equipment installation,and the actual size is subject to the site manual |

|

The parameters are for reference only,please refer to the actual equipment |

|

*Run-Length varies with its printing conditions and imaging content

GET A QUOTE