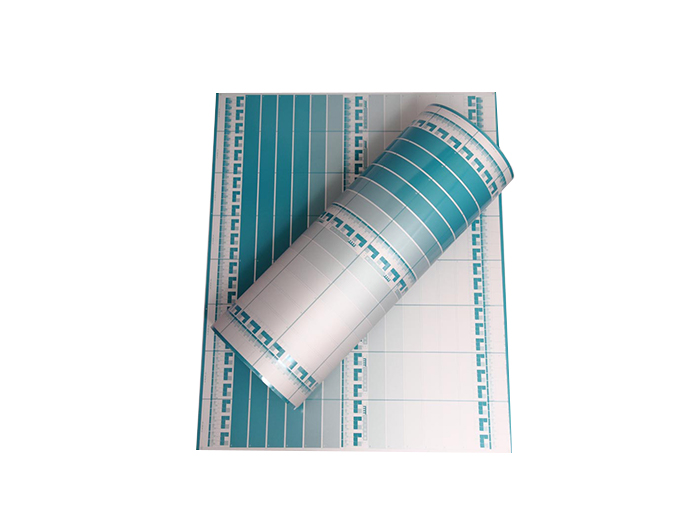

A softer digital plate than SF-DGL, which is suitable for label and tags, folding cartons, and sacks, paper, multiwall printing

Increased productivity and data transfer without loss of quality due to digital workflow

Consistency in quality when repeating plate processing

Cost effective and more environmentally friendly in processing, as no film is required

Excellent ink transfer using water and alcohol-based inks

Suitable for labels, tags, flexible packaging, sacks, folding carton, films and so on

| Thickness (mm/inch) | Hardness (Shore Å) | Total Range(%) | Screen Ruling(LPI) | Minimum Isolated Line | Minimum Isolated Dot |

| 1.70/0.067 | 62 | 1 ‒ 98% | 150 | 0.1mm | 0.15mm |

| 2.54/0.100 | 55 | 2 ‒ 95% | 150 | 0.1mm | 0.15mm |

| 2.84/0.112 | 54 | 2 ‒ 95% | 130 | 0.15mm | 0.2mm |

| Thickness (mm/inch) | Back Exposure (s) | Main Exposure (mins) | Wash out (mm/mins) | Drying Time (h) | Post Exposure (mins) | Detack(mins) |

| 1.70/0.067 | 50-70 | 10-15 | 140-180 | 1.5-2 | 5min | 4min |

| 2.54/0.100 | 20-50 | 10-15 | 130-170 | 2-2.5 | 5min | 4min |

| 2.84/0.112 | 20-50 | 10-15 | 120-140 | 2-2.5 | 5min | 4min |

*Run-Length varies with its printing conditions and imaging content

GET A QUOTE