Apr 21,2025

In an era where environmental awareness is at an all - time high, the printing industry is under increasing pressure to adopt more sustainable practices. One of the most significant advancements in this regard is the rise of thermal CTP (Computer - to - Plate) plates, which are rapidly changing the way printing businesses operate, making them more eco - friendly and cost - effective.

Traditional Plate Challenges: Traditional printing plates, especially those using photosensitive technologies, often need a complex and chemical - intensive development process. Silver - salt materials, commonly used in photosensitive imaging, are not only expensive but also pose a big environmental risk during development and washing. If these chemicals are not disposed of properly, they can cause water pollution and soil degradation.

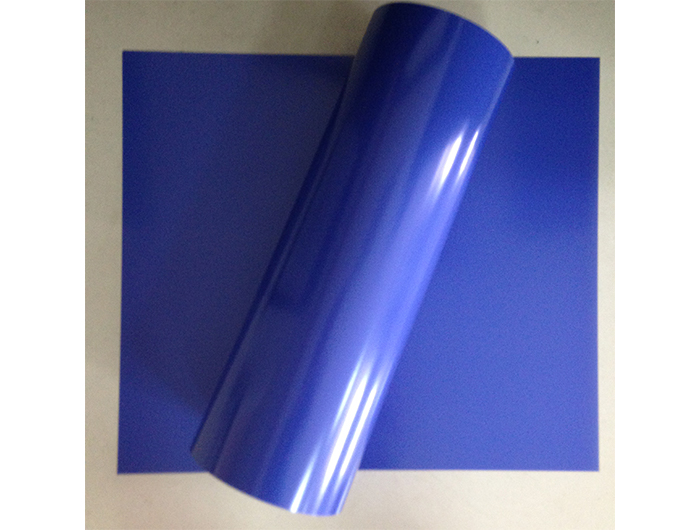

Thermal CTP's Advantage: Thermal CTP plates use a thermal imaging principle. The infrared laser exposure system in thermal CTP technology can directly image on the plate without needing many of the harmful chemicals used in traditional processes. This not only lessens the environmental impact but also simplifies the plate - making process, saving both time and resources.

Energy - Consumption Comparison: The thermal imaging process of thermal CTP plates uses less energy compared to some other plate - making technologies. The precise heat - based activation of the plate's coating makes sure that energy is only used when necessary, reducing waste.

Bright - Room Operation Benefit: Also, thermal CTP plates can be processed in a normal, bright room. This is different from photosensitive plates that need darkroom conditions. So, there's no need for extra energy - consuming lighting and ventilation systems for darkroom operations. This energy - saving feature helps printing companies lower their carbon footprint and cut down on operational costs in the long run.

High Impression Capability: Thermal CTP plates, especially when baked, can achieve a very high number of impressions, often up to 1 million or more. This long - lasting performance means that for high - volume printing jobs, fewer plates need to be made.

Resource Conservation: Reducing how often plates need to be replaced saves on raw materials and also cuts down the waste from discarded plates. Plus, the high - quality and consistent printing results from thermal CTP plates mean there's less chance of having to reprint because of bad print quality, which further saves resources.

In conclusion, thermal CTP plates are at the front of the sustainable printing revolution. Their reduced chemical use, energy - efficiency, and durability offer a three - fold solution to the environmental and cost problems in the printing industry. As more and more printing businesses try to meet the growing demand for sustainable products and services, thermal CTP plates are going to be an important part of the modern printing process. Whether you run a small - scale print shop or a large - scale commercial printer, using thermal CTP plates is not only a step towards a greener future but also a smart business move that can help your business grow and succeed in a more competitive market.

GET A QUOTE